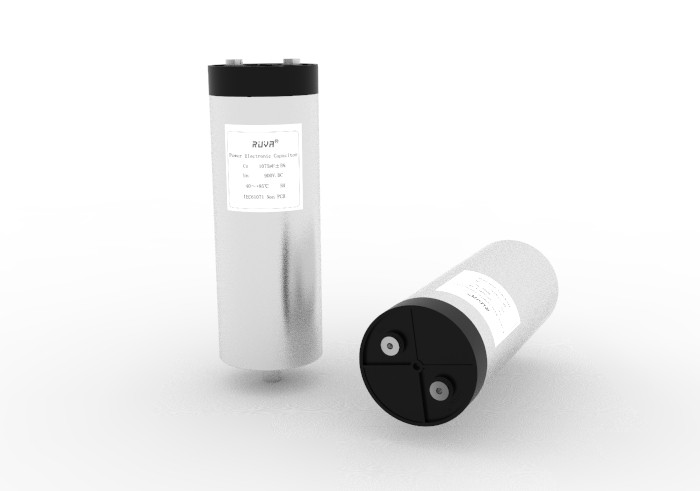

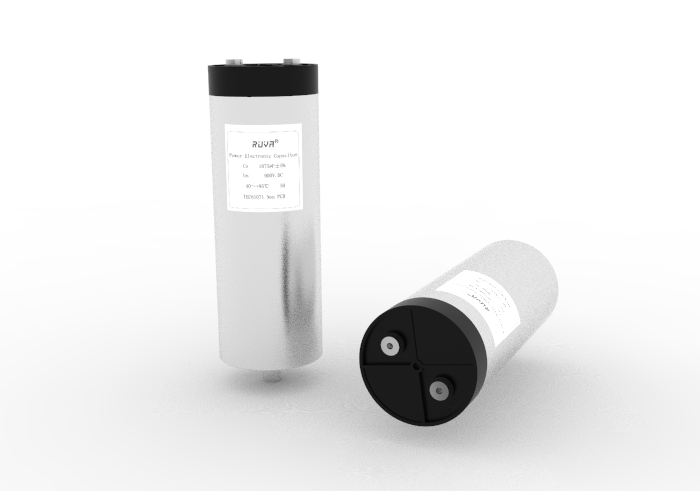

YHA Dry Type DC Filter Capacitor With Aluminum Can

- RUVA

- CHINA

- 3 Weeks

1. High ripple current

2. High impulse current

3. Low inductance

4. High reliability and long life time

5. Shock and vibration proof

6. Widely applied in wind turbine converters

Power Electronic Capacitors - YHA Series

INTRODUCTION

YHA series represents a new generation of DC-Link capacitors.YHA series capacitors are cylindrical aluminum shell structure, stud electrode, fixed by bolt at the bottom, internal epoxy pourting dry structure.It has good electrical performance and environmental adaptability. The expected service life of YHA is up to 100 000 hours, the inrush current capacity is increased to 300IN, and the can size is reduced, which makes YHA an ideal capacitor for industrial applications requiring high reliability.

FEATURES

High ripple current

High impulse current

Low inductance

Shock and vibration proof

Metallized polypropylene with high performance and lower weight

Cylindrical extruded aluminum case, compact integrated structure

Dry filled, good anti-vibration performance and no leakage

Tightly sealed, good environment adaptability

Long life expectancy up to 100 000 hours at temperature class -40/85

Low dissipation factor, high pulse current withstand capability

Used in DC-Link circuits,be able to replace electrolytic capacitor

Good self-healing and voltage withstand, high long term stability

APPLICATIONS

DC link in low-power drives

DC link in wind turbine converters

High voltage frequency converters, SVG, SVC, etc

Impulse discharge capacitors for magnetizing and welding

TECHNICAL PARAMETERS

| Rated DC voltage min. | 600 VDC |

| Rated DC voltage max. | 1500 VDC |

| Capacitance min. | 90 μF |

| Capacitance max. | 5600 μF |

| Capacitance tolerance | ± 5 % or ± 10 % |

| Technology | Metallized polypropylene film, self-healing |

| Dielectric dissipation factor | < 2 x 10-4 |

| Climatic category | 40/85/21 |

Storage Temperature | -40°C ~ 85°C |

| Operating temperature min. | -40°C |

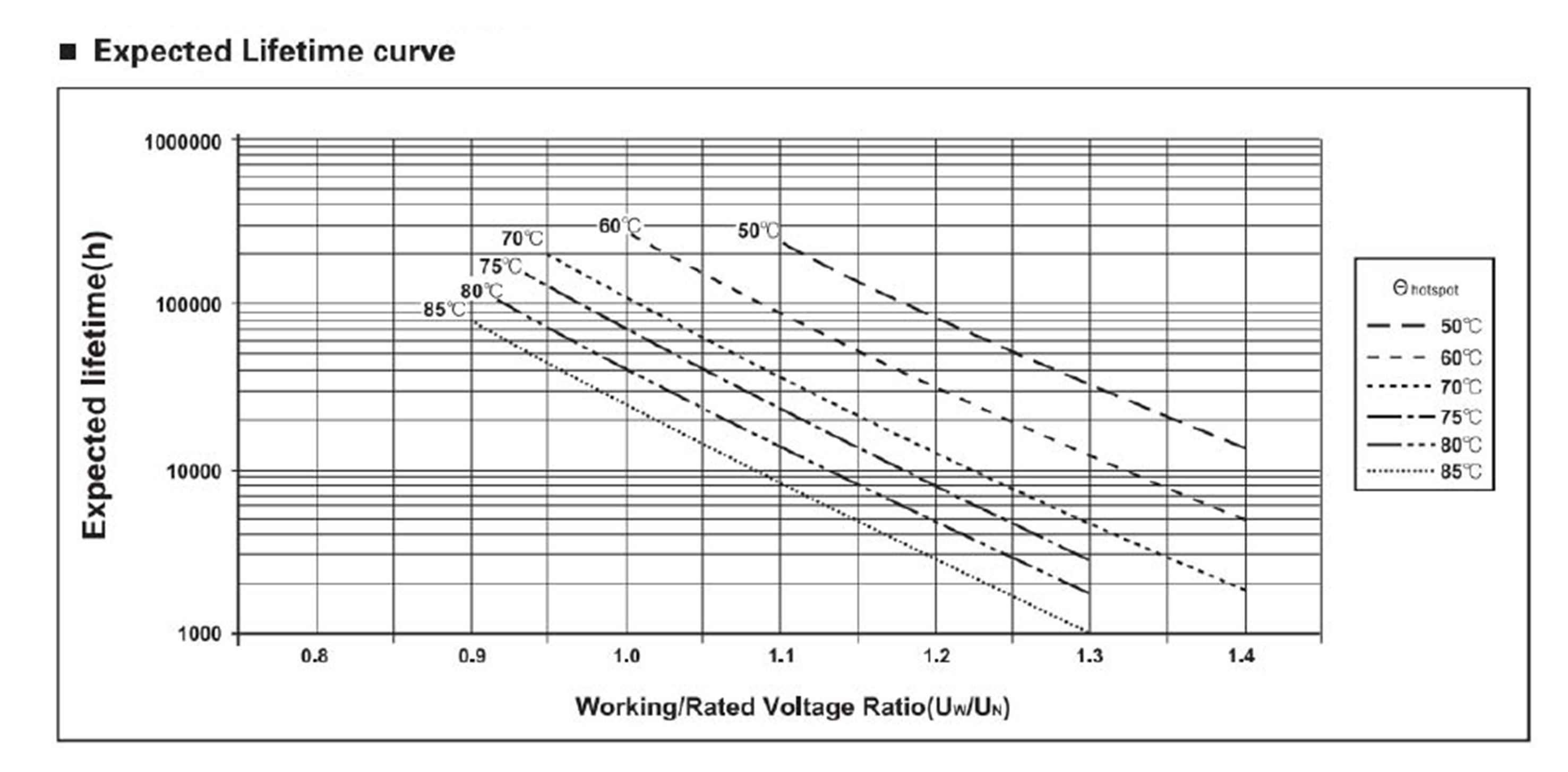

| Operating temperature max. | +70°C (θhotspot≤85°C) |

| Max. Humidity Hmax | 95 %RH |

| Max. Altitude | 2000 m |

| Insulation resistance (Ri×CN) | ≥ 5000s (500V, 20℃) |

| Inductance | < 100 nH |

| Lifetime expectancy | > 100 000 h at UNDC and < 70 °C hotspot |

| Reliability | < 100 FIT |

| Test voltage | Utt = 1.5 x UNDC/10 s; Utc = 4000VAC (50Hz, 20°C,10s) |

| Casing | Aluminum / plastic |

Cooling | Natural or forced cooled |

Terminal | Tinned brass |

Max Torque of terminals | 5N·m (M6) |

Max Torque of installation | 10N·m (M12) 13N·m (M16) |

| Filling | Dry resin (UL 94 V-0) |

| Standard | GB/T 17702-2013 (idt IEC 61071:2007) |

| Certificate | TUV |

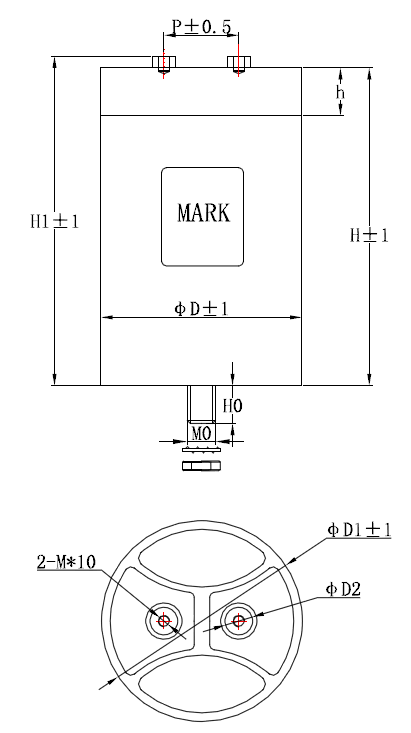

OUTLINE DRAWING

| D | D1 | P | H | M0xH0 | H1 | M | D2 |

| 76 | 76 | 32 | 20 | M12x16 | H+5 | M6 | 16 |

| 86 | 86 | 32 | 20 | M12x16 | H+5 | M6 | 14 |

| 86 | 88 | 32 | 35 | M12x16 | H+4 | M6 | 12 |

| 96 | 97 | 45 | 30 | M12x16 | H+5 | M6 | 15 |

| 116 | 116 | 50 | 22 | M12x16 | H+5 | M6 | 16 |

EXPECTED LIFETIME CURVE

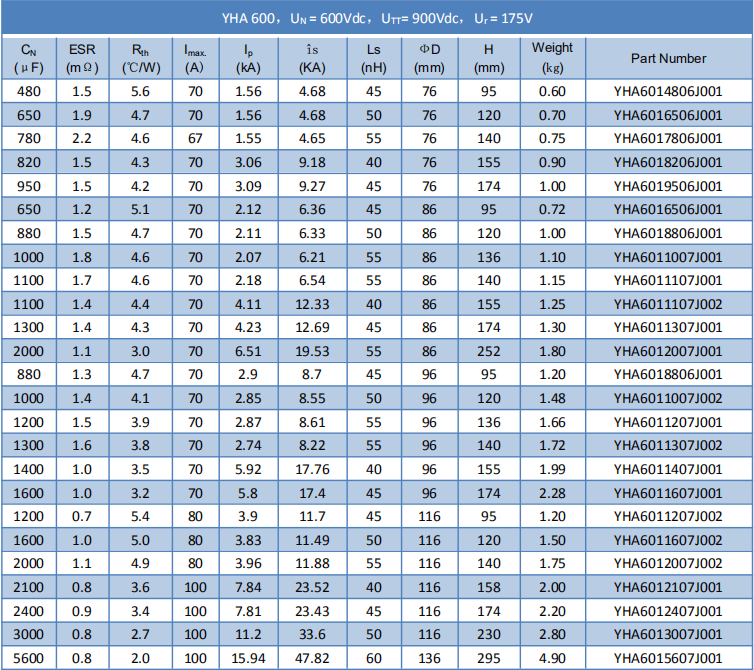

TECHNICAL DATA

PRODUCT DETAILS

Case: Aluminum case

Terminals: Tinned brass

Epoxy: Thermally conductive resin

Case: Aluminum case

Epoxy: Thermally conductive resin

Mounting and grounding: Threaded M12 or M16 stud on the bottom of the case